A WOMBAT, a crow and two entrepreneurs – these are the four characters powering Australia’s last remaining spectacle manufacturing business.

Two years ago John Hansen and Gino Trigatti joined forces to turn around an ailing 52 year-old Dubbo business called Optex.

The pair had worked together for about 20 years at a large steel fabrication business in Brisbane but something caught Mr Hansen’s eye one day which led to a new venture in spectacle manufacturing.

“John saw his friend, an accountant, wearing a pair of round glasses one day and he learned they were from a company here in Dubbo,” Mr Trigatti tells the story.

“Over a counter lunch the accountant told John the company behind the glasses was losing money. Immediately, John started scribbling numbers on a napkin and he figured there was an opportunity to turn this company around.

“John contacted me about the business. I said good luck with that one, mate. I knew nothing about eyewear. I didn’t even know how glasses were made. I don’t think anyone really does.”

But Mr Trigatti’s arm was twisted.

In 2015 the pair re-branded Optex to Clive and Wally – their logo includes a cheeky crow representing the two mens’ late business mentor and an old pet wombat.

They moved the businesses’ premises from Dubbo’s industrial centre to Talbragar Street and haven’t looked back.

EYEWEAR FOR ALL

Clive and Wally owners John Hansen and Gino Trigatti believe there’s ample scope to grow the business.

Australia has 5000 registered optometrists, including the big chains, and 8.5 million people wear prescription glasses.

“We need only one per cent of the market to be making 80,000 frames a year,” Mr Hansen said.

Currently the business makes fewer than 700 frames a month. Its goal is to produce a minimum 1500 frames a month.

WHY DUBBO WORKS

Optex was launched by newly-wed Irene and Paul Luthy in 1963. She was a keen fashion designer and he had gained optical tooling experience in Switzerland.

After Mr Luthy’s death, Mrs Luthy, now 84, struggled to run the business alone.

Mr Hansen and Mr Triggatti can see why she struggled. There are huge costs associated with manufacturing in Australia.

“We have to ship in all our products and components because they don’t make them here in Australia. I have to pay for it before it leaves its destination. Then there’s the cost and time involved in getting it all from Sydney to Dubbo. We’re competing with the French, the Italians and, of course, the Chinese. It makes it very difficult for us to compete.

“Plus, if anything breaks down with my machines I have to bring in the parts from Italy.”

“We started with four employees and we’re now a team of nine.”

- Gino Trigatti

So, why persist in Dubbo?

“Rent is cheaper here but it’s more than that. We’re passionate about the bush,” Mr Triggati said.

“For me, jobs and quality is very important. It just saddens me to see how many Australian companies have gone by the wayside. It is difficult at times but we’re committed to making this business work.”

KEEPING IT LOCAL

New to the world of eyewear, Clive and Wally’s owners learnt the value of their specialised workforce very quickly.

“We thought about relocating the business to Brisbane but we had to think of the four people who worked here and their experience.

“We started with four employees and we’re now a team of nine.”

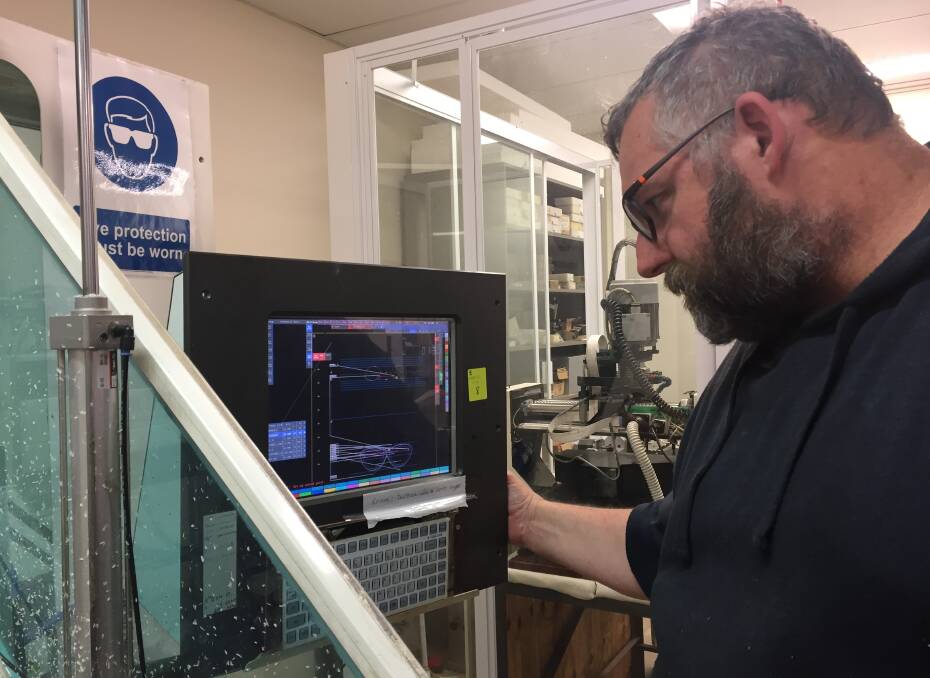

Clive and Wally’s latest local recruits are engineers.

“We just hired two more ladies who migrated from India to Australia. One is a civil engineer and one is an electrical engineer. They’re helping us with computer programming which is terrific.”

As well as employing locals, Clive and Wally rely on the services of other local businesses like glass cutters.

The added benefit of that, Mr Trigatti said, is customers can receive a same-day service.